Lead-Lined Drywall & Gypsum Board

Lead-lined drywall, also called sheetrock, consists of gypsum board laminated with sheet lead to provide radiation shielding from high-level gamma ray and x-ray radiation. Radiation Protection Products is proud to be your top supplier of lead-backed drywall solutions for any industry. We provide durable, effective radiation shielding products that meet or exceed any industrial specification, such as:

- ASTM C1396 Standard Specification for Gypsum Board

- ASTM C840 Standard Specification for Application and Finishing of Gypsum Board

- Federal Specification SS-L-30D Grade X Type III for Gypsum Board

Don’t see the specification, configuration, or lead-backed drywall thickness your application requires? Contact us or call 888-746-4777 to explore your options. One of our expert engineers will be in touch as soon as possible to find the best radiation shielding product for your hospital, x-ray room, or other operation.

Lead-Backed Drywall for Effective Radiation Shielding

Lead-lined walls from RPP consist of a single, unpierced sheet of lead laminated to a specified drywall thickness. Choosing our radiation shielding products delivers many advantages and benefits:

- Fire Code sheetrock used exclusively in all lead-lined drywall products

- Pure lead cast and rolled in-house to ensure quality

- Industrial-grade adhesives to keep lead lining secure

- And much more!

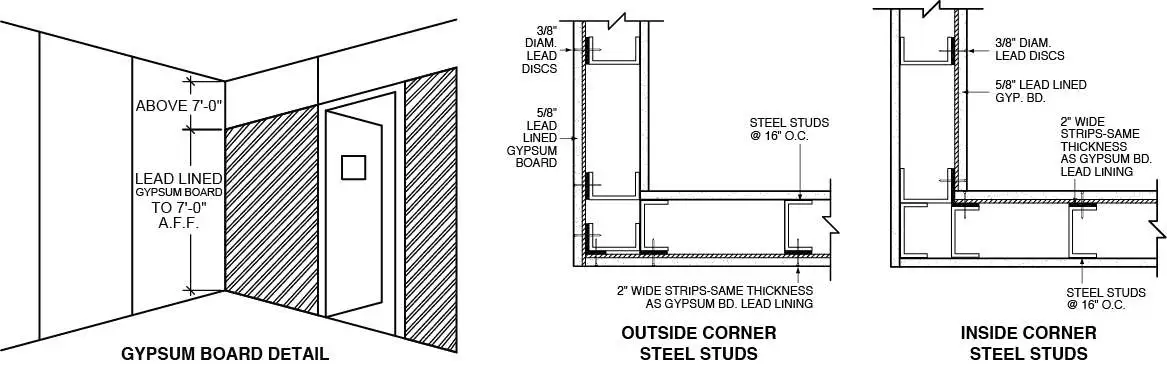

View our CAD drawings and submittals for a full listing of lead-lined sheetrock sizes and specifications. Always work with a licensed radiation health physicist to assess your required lead thickness. All fastener penetrations, light switches, air ducts, and other receptacles will require cut-out and penetration radiation shielding products to prevent leakage.

Product options include:

| Feature | Standard Options | Custom Options |

| Drywall Thickness | 1/2", 5/8" | Other thicknesses on request |

| Drywall Height | 8', 9', 10', 12' | Heights outside this range available |

| Lead Thickness | 1/32", 3/64", 1/16", 5/64", 3/32", 7/64", 1/8" | Intermeidate sizes available. For thicknesses over 1/8", we recommend using plywood |

| Lead Height | 7'-12' | Custom lead heights available |

| Joint Shielding | 2" lead strips (matching wall thickness/height) | Can be modifed to project-specific needs |

| Fire Code Compliance | Fire-rated drywall used exclusively | Mold/moisture resistant options available |

Request a Quote for Lead-Lined Drywall

Standard Lead-Lined Drywall Configurations

Standard lead-backed walls are ideal for hospitals, dental clinics, x-ray rooms, and many other industrial facilities working with radiation. To meet the varied needs of such an extensive range of requirements, RPP stocks standard lead sheetrock to meet your needs:

- 1/2" or 5/8” thicknesses

- Lead-lining thicknesses up to 1/8” with optional double layering

- 2” wide lead strips of the same thickness and height as walls provided for sealing vertical joints

Lead-Lined Gypsum Installation & Wall Weight Estimations

Wall weight and installation are critical considerations for construction with lead-lined drywall. Typically, lead-backed gypsum is installed by hanging panels vertically with drywall fasteners at a minimum of 8” on center at the sheet wall edges and a minimum of 12” on center at intermediate studs.

The joints are sealed to existing metal studs using the 2” lead battens and leaded fastener disks to protect against radiation leaks. Instead of leaded disks, lead angles provide a more streamlined and seamless installation. Ensuring complete protection against radiation also requires the shielding of penetrations and cutouts; if angles are used at seams and studs, fastener penetrations will not need extra shielding. Our lead-lined gypsum weights for installation are as follows:

For lead thicknesses exceeding 1/8”, please refer to our lead-lined plywood requirements and specifications.

Custom Specifications & Thicknesses for Lead-Backed Walls

We offer lead lining bonded to moisture and mold-resistant gypsum board in custom sizes for specialty radiation shielding applications. Custom lead-lined walls can be attached using standard coarse drywall screws and can be tailor-designed to fit your exact requirements. Request a quote to receive more information about our custom capabilities specific to your planned use.

X-Ray and Radiation Shielding Products for Hospitals and Other Facilities

Hospitals, laboratories, and other facilities require lead-lined walls that prevent harmful or prolonged radiation exposure to workers, patients, and other individuals. Our lead-backed drywall and other radiation protection products are designed to provide long-lasting and comprehensive shielding in any application, such as:

- C-ARM radiography

- X-ray imaging

- P.E.T. and CT scan rooms

- Fluoroscope rooms

- Nuclear medicine rooms

- Non-destructive testing applications

- Laboratories

Contact RPP to Discuss Lead-Lined Sheetrock & Lead Shielding Products

Radiation Protection Products works with architects, drywall supply houses, and contractors to handle lead-shielding projects of all sizes. Our dedication to customer service includes fast quote turnaround and nationwide shipping, including Alaska and Hawaii. For projects with larger scopes, we offer turnkey services and installation assistance.

Contact us to discuss options for mold-resistant lead-lined drywall or our other services and capabilities. Request a quote to begin your order for lead-backed drywall. We will be in touch within one business day.